Description

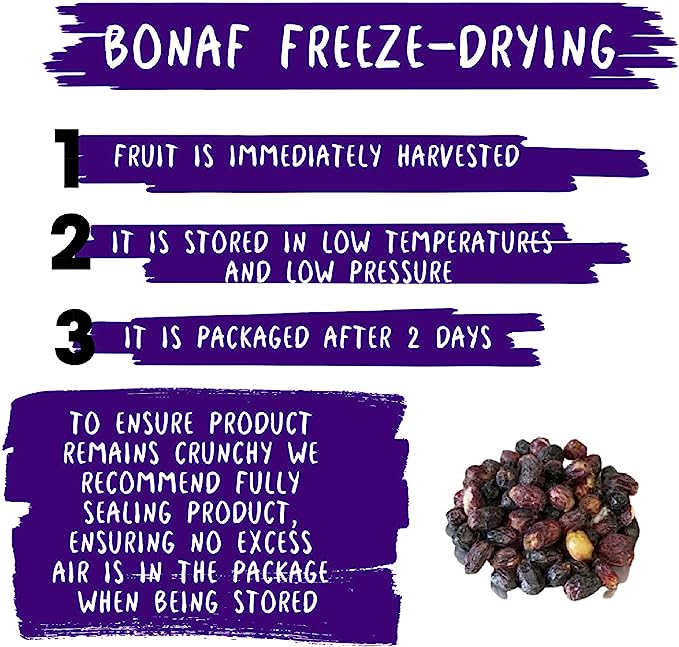

The freeze-drying process, also known as lyophilization or sublimation, consists of two main stages. Initially, fresh cut products are transported in to so-called “Blast Freezer” and frozen below -40C temperature. Once products are deeply frozen, they are put into a freeze-drying chamber where a vacuum is created by lowering the air pressure a certain degree.

Afterward low temperature heat is transferred to products through the shelves of the freeze-drying chamber and ice in the product becomes gas bypassing the liquid phase. The whole process may last from 24 hours up to 40 hours depending on the type, size, and amount of the product. Almost 97-98% of the water will be sublimated from products during the freeze-drying process.

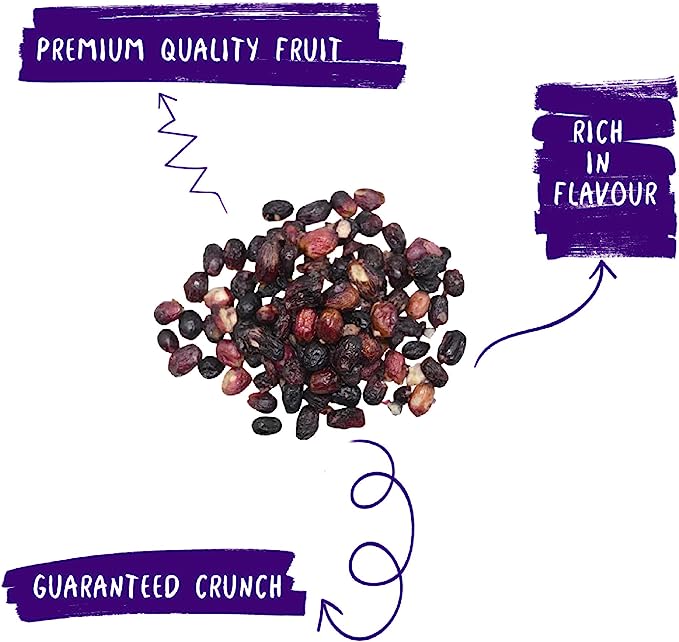

- 100% Real Fruits

- No Preservatives

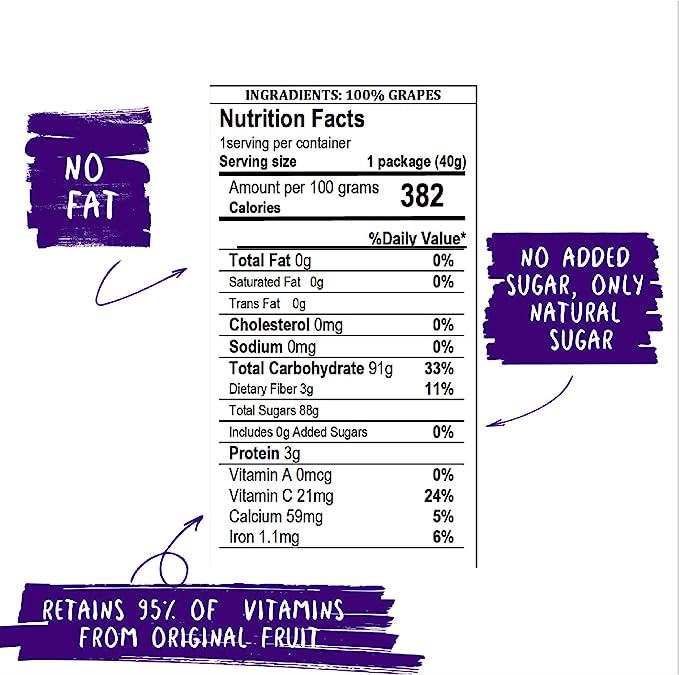

- No Sugar Added

- GMO-Free

- No Additives